Being a pioneer in intelligent machinery and technology, we are skilled in increasing production efficiency and guaranteeing the highest standards of quality in the electric car industry. We work hard to give our partners the resources they need to be successful because we recognize how important accuracy and dependability are to the battery production process.

Comprehensive Camera Test Solutions

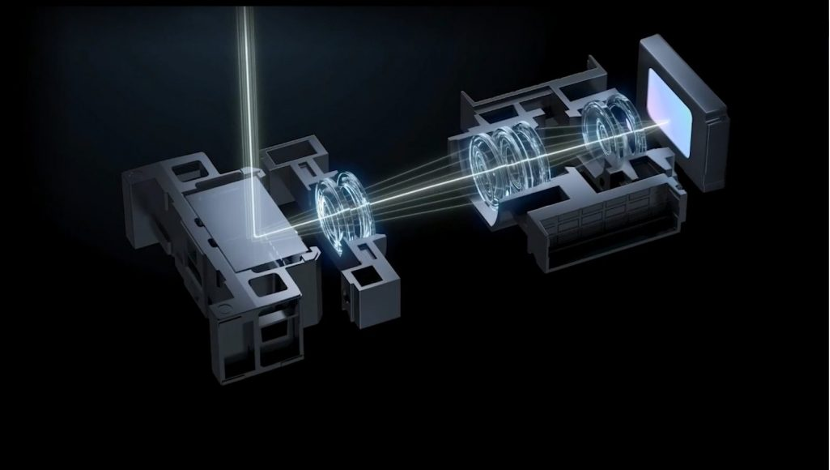

One of our flagship offerings for EV battery manufacturing is our comprehensive camera test system. This fully automatic whole line solution integrates 3D pad printing, screen printing, and advanced inspection processes. Our technology features high-precision visual-guide alignment and Automated Optical Inspection (AOI), ensuring that every component meets stringent quality criteria. By implementing our camera test solutions, manufacturers can streamline their production processes while maintaining the highest standards for their EV batteries. Our aim is to support our clients in achieving optimal performance and safety for their products through reliable manufacturing practices.

High-Bandwidth Camera Image Testing

Furthermore, our camera image test feature is designed specifically for high-performance requirements in EV battery manufacturing. With 40G high-bandwidth and high-speed graphics capture capabilities, we enable manufacturers to obtain rapid and accurate visual data during the assembly process. This speed and reliability are crucial in the fast-paced environment of EV battery production, allowing for real-time monitoring and adjustments to be made. By utilizing our advanced camera image testing technology, businesses can ensure that their products consistently meet quality benchmarks, leading to increased customer satisfaction and loyalty.

Innovative 3D ToF Testing

In addition to camera image testing, we also provide an innovative 3D Time-of-Flight (ToF) testing solution for EV battery manufacturing. Our customizable Tx/Rx and sensor detection calibration technologies help manufacturers assess the precise dimensions and integrity of their battery components. This capability is vital for ensuring that all elements fit together seamlessly, which is essential for optimal performance and safety in electric vehicles. Through our 3D ToF testing solutions, companies can enhance production accuracy and minimize potential issues down the line.

Conclusion

In conclusion, LEAD is dedicated to revolutionizing the EV battery manufacturing process by providing advanced technological solutions that address the industry’s unique challenges. From our comprehensive camera test capabilities to high-bandwidth image testing and cutting-edge 3D ToF testing, we offer complete solutions that enhance operational efficiency, precision, and quality. As the demand for electric vehicles continues to grow, our commitment to innovation ensures that our partners can scale their production while maintaining the highest standards. Selecting LEAD as your reliable EV battery production partner puts your company in a successful position in a cutthroat industry.